Price hikes in cooking gas cylinders are becoming an increasing cause of worry, at both domestic and commercial levels. But a cost-friendly innovation by researchers at IIT-Guwahati might be the solution. The team has developed the Porous Radiant Burner (PRB), which could replace conventional burners. Developers say the PRB will be low on emission, save fuel costs by 40%, and reduce cooking time by 30%. It can work on a range of fuels and can serve both commercial and domestic needs.

P Muthukumar, professor at IIT-Guwahati and the head of the research team, says the reason behind conceiving such technology was to address the multiple factors that dominate the decision to use clean cooking energy. “Availability and affordability of fuel, health, efficiency and eco-friendliness are some factors that determine the choice of the fuel bought. There was a need for a burner that would address all these concerns at the same time,” he says.

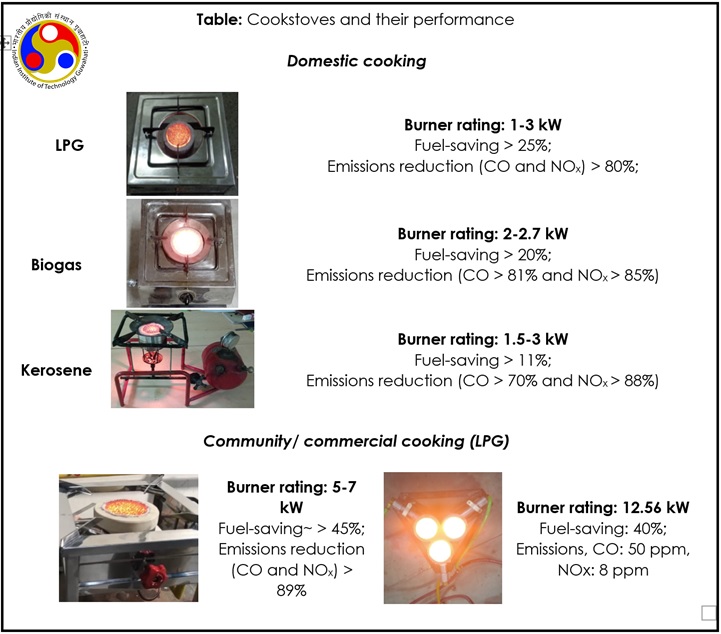

The new burners can accommodate the aforementioned factors while working on different fuels such as LPG, biogas and kerosene.

Flameless burner

Muthukumar says, “Conventional burners are not efficient, as heat transfer from free flame combustion to the vessel is not effective. Besides, much of the heat is lost to the surroundings, thus reducing the efficiency of the stove. However, the new burners, which use porous media combustion, do not contain any flames and permit the transfer of heat to the vessel through combined modes of conduction, convection and volumetric radiation. The technology helps reduce the heat lost to the surroundings, and increase heat transfer.”

The radiation from PRBs allows heat to travel at the speed of light, thus increasing efficiency. This also comes due to the uniform heat transfer around the vessel. These factors, in turn, help the food cook faster. “The arrangement helps reduce the emission of toxic gases like carbon monoxide, nitric oxide and nitrogen dioxide up to 80%. This makes the cooking healthier and environment friendly,” he adds.

Muthukumar says the burner is made from ceramic such as alumina and silicon carbide and can withstand heat at high temperatures. Scientists on the team say they have tested the burner in commercial and domestic setups. “Experiments were conducted to cook food such as rice, dal, vegetables, meats, paneer and other varieties as per the national average menu. The overall time saved, when compared with conventional burners, was 30%,” he adds.

Not limited to research

However, optimising efficiency to this extent was an uphill task. Lav Kumar Kaushik, one of the researchers on the team, says, “Such technology is used in boilers and other commercial establishments. The first task was to scale down and adapt a technology that would work on a small scale. The additional challenge was to develop burners with different configurations, which could address distinct fuel requirements and their burning characteristics. The burners perform equally well under different scenarios such as domestic or commercial cooking.”

Lav says that considerable time was spent to modify each burner according to the needs. This was done by changing their porosity, density and diameters. “These burners were tested in the lab and in kitchens. The product complies with the BIS standards of the Government of India,” he adds.

However, these burners cannot be retrofitted, and require a new cookstove. The scientists have signed an MoU with a company and are in the process of commercialising the technology. The product is expected to be rolled out by 2022. “We will ensure that the cost of these cookstoves remains at par with that of conventional burners,” Muthukumar says.

Edited by Divya Sethu

No comments:

Post a Comment