At 22, Firoza Kothari from Mumbai, a Biotech engineer scripted history via 3D printing. She helped save the life of a 9-month-old with an abnormal hole in the heart. She created a replica of the infant’s heart, a stint that was touted as a first for cardiac 3D printing in India.

His pulmonary artery and aorta came from the right ventricle instead of the former which typically comes out of the left. The doctors at Fortis Hospital were in a fix as the heart was too small to operate on and the surgery carried huge risks. That’s when the surgical team reached out to Sahas Softech LLP, a 3D printing venture founded by Firoza’s brother, Sohrab Kothari and his friend Sagar Shah. Firoza had just joined the company and it was their first experiment in the healthcare sector.

After an in-depth study of the case, it was Firoza who came up with a 3D replica of the heart from the baby’s MRI scan within 48 hours. The surgeons practised the procedure by opening the heart chambers, analysing blood flow and shifting the arteries.

“In the absence of the heart model, it would have been difficult to confidently opt for a complete repair of the heart using an intra-cardiac tunnel or baffle,” Dr Vijay Agarwal, the lead surgeon on the operation told 3Dprint. The artery was successfully shifted from the right ventricle to the left through the heart’s hole.

Four years after the surgery, Firoza launched Anotomiz3D along with Sagar and Sohrab that exclusively caters to healthcare. The ISO-certified venture uses various technologies of 3D printing to provide custom-based implants, prosthetics, orthotics for patients.

“We use CT/MRI images as inputs to make the 3D models that can help eliminate risks with mock-surgeries or pre-planned procedures. The doctors can make precise cuts and drills and understand the thickness, angle and location of the organs. Additionally, it helps in bridging the demand and supply gap of organ or tissue availability. Overall speaking, It reduces the complications and surgical time,” Firoza tells The Better India.

The 2015 surgery helped Anotomiz3D establish its credibility in the field, and so far it has worked with over 200 hospitals across India, including Apollo Hospital, AIIMS Kochi, AIIMS Delhi, Lilavati Hospital, Max Hospital and so on. “We have made 3D models for nearly 1200 surgeries,” the 28-year-old adds.

How 3D Printing Works In Medicine

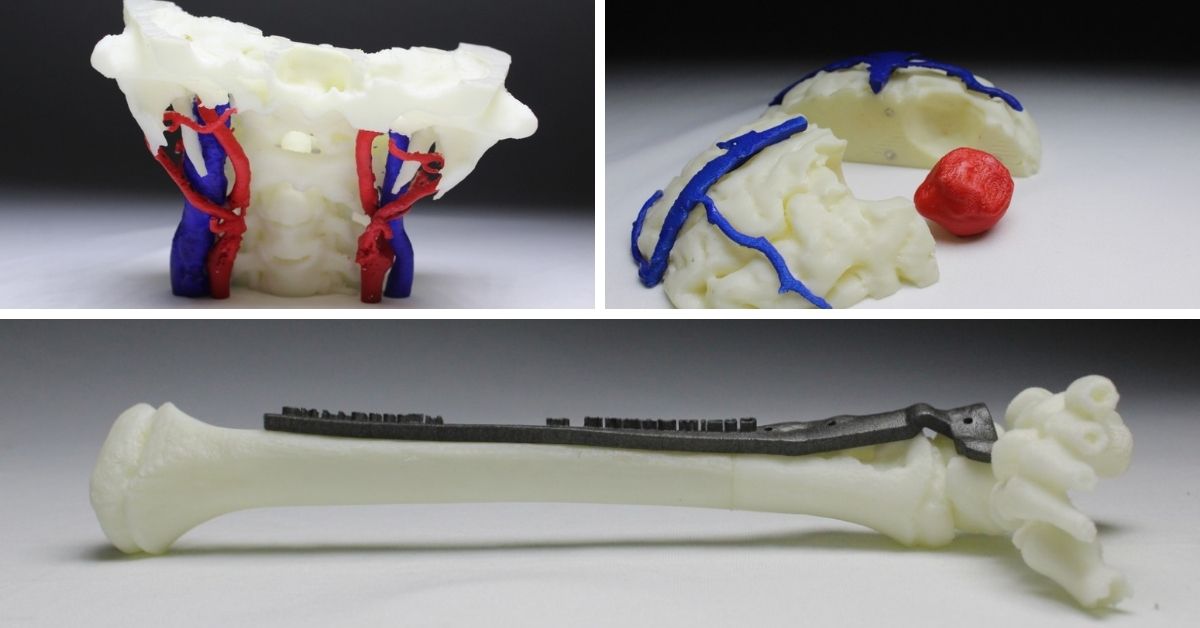

The services and products provided by Firoza’s company can be divided into three categories — anatomical models for pre-surgical planning and education, implants and providing cutting and drilling guides for doctors.

As for the process, a patient’s CT or MRI scans are needed for radiological data. Based on that, the venture identifies the patient’s anatomy and uses different techniques such as Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Digital Light Process, Multi Jet Fusion and PolyJet to print. The final product can be powder or metal-based.

Explaining the process, Firoza says, “The image of a particular organ can be saved as a file on the desktop which is then deposited into the 3D printer. The result comes out as a physical model.”

Take for example a 3D model of a tongue for a Bengaluru-based Quinquagenarian using Materialise Mimics software. The technology digitally separated the tumour from the tongue through an MRI scan. It mimicked the tongue’s properties and printed it in a different colour. In 2016, the doctors at Health Care Global (HCG) operated on the model and then removed the tumour in the OT.

Firoza recently ventured into a new arena with the introduction of 3D-printing labs in Apollo (Hyderabad) and Maxwell (Delhi). The lab allows doctors to build anatomical models and customised implants.

“With the hospital 3D-printing labs, the future of healthcare is here. Personalisation of healthcare is the new mantra and advances in genomics and precision medicine are driving personalised prevention and treatment. From specialised medicines for targeted therapies to customised implants and prosthetics, 3D-printing technology is transforming the medical environment, providing a fast, accurate and economical solution to take medical care to the next level,” Apollo Hospitals chairman Dr Reddy told Fortune India.

Costs, Learning & Challenges

For the longest time, Firoza, Sohrab and Sagar tried to attend as many surgeries as possible to understand the technicalities inside an operation theatre. In the very beginning, they realised an in-depth understanding of bones, arteries, fat, muscle skin, etc is needed in order to match the replica with the organ proficiently.

Being from a non-medical background also made the health experts’ clinical language challenging. “We have kept eight doctors from different specialisations in our advisory board to ensure there are no knowledge-related gaps. This has helped us build better models over time,” says Firoza.

The team is also trying to address the high cost and lower it by experimenting with different manufacturing parts. For example, the bones manufactured by the venture cost around Rs 5,000 against the average market price of Rs 25,000.

“Although cost could be a deterrent, 3D printing is a very viable option, especially in custom made joint replacements. With the booming medical tourism and improving standards of living, we can increase the scope of 3D printing in India. We can use Artificial Intelligence to make the process faster and more efficient,” Dr Alpa Bharati, Cardiac Imaging Consultant, at Wadia hospital (Mumbai) who is in the advisory committee tells The Better India.

That said, Firoza admits that there have been surgeries that did not go according to plan due to several reasons such as models based on old scans, realising the reality of the organ is different while operating or designs. With guidance from the advisory board and doctors with whom they collaborate, the team fixes the errors.

Due to quick learning and efficiency, Anotomiz3D has built 3D models for various departments, including cardiology, neurology, paediatrics, orthopaedics, among others.

As seen in the case of Antomiz3D, the 3D printing market is filled with untapped potential. As per the industry statistics, it is a booming market. According to a report by Guardian, the 3D printing industry is predicted to be worth over $1.3 billion in 2021. One can hope that in the coming years we will witness a technological revolution with invaluable visualisations and cost-saving procedures that can improve countless lives.

Get in touch with Antomiz3D here

Edited by Yoshita Rao

No comments:

Post a Comment