IIn 2019, The Better India had covered Shriti Pandey, an architect from Uttar Pradesh, for her innovative techniques in building sustainable homes from agricultural waste. Little did we know that she would be using the same formula to build two COVID-19 facilities on the outskirts of Patna and Jalandhar, Punjab to meet the rising demand for beds a year later.

The civil engineer took less than 80 days to set up a fully functioning centre in Patna for her client ‘Doctors For You’ (DFY), in collaboration with the Selco Foundation. The second unit was set up in Jalandhar in collaboration with the Batra Hospital.

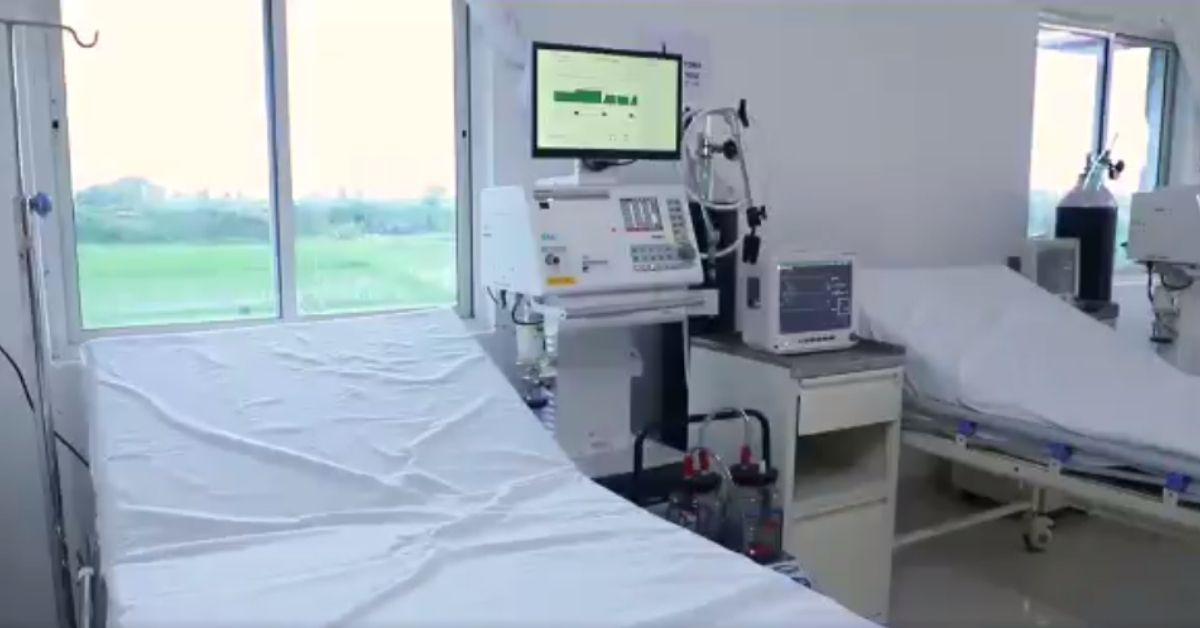

“In March 2020, we had to shut our operations due to the lockdown. In April, Selco approached us to construct a facility that would be cost-effective, eco-friendly and one that could be built quickly in Masehri. By July we handed over the 6,000-square feet facility, which has a capacity of 75 beds. There are separate rooms for patients that require oxygen cylinders and ventilators,” Shriti tells The Better India.

One of the highlights is that zero water was used to build the facility, and it entirely runs on solar power. Shriti shares how she achieved the daunting task and is presently building similar structures in other areas.

Fireproof, solar-powered & more

Reading the signs of worsening climatic conditions and the catastrophe bound to happen in the future due to our current consumption habits, Shriti adopted a technique similar to a European company, Ekopanely, which uses recyclable and vapour permeable construction panels as a building material.

Shriti makes fibre panels, a sustainable alternative to concrete walls and ceilings, from agricultural waste. The straw core of the Strawcture board is encased in three layers of recycled paper. After the board is installed into a structure, the surface is penetrated and a final finish is applied that prevents rodents from entering the building. The straw panels can last for up to 100 years. The micro-pores created on the panel absorb and retain humidity until the temperature conditions change for the better. The board then releases the humidity, moistening the air inside the room.

“We use silica, which makes the wall fireproof, and each wall structure can store up to three kilos of carbon dioxide. Each panel is inherently thermally insulated which means it absorbs heat and keeps the interior cool, which is conducive to patients with breathing discomforts. The roof has a corrugated sheet that also absorbs the heat. Selco was mindful of the electricity problems in the area and no medical facility can run without it. We installed the solar panels on the roof, which provides power for the entire facility, thus making it self-sufficient,” explains Shriti.

Although the structure is made entirely from fibre panels, the look of the facility including washrooms and rooms are like any other conventional building. The team used a lamination technique to make the floors extra durable due to the regular use of disinfectants and sanitisation.

Time and cost-effectiveness

Around 60% of the construction work took place offsite, in Shriti’s workshop. The team opted for using screws and bolts to assemble the pre-done structures instead of welding to save time. It took them five days to put 400 wall panels. They have reduced the weight of the entire foundation by using foam-like material. Both these strategies helped Shriti, Selco and DFY cut down costs.

Shriti and her team is presently working on introducing foldable and movable partitions for hospitals that can easily be converted into rooms or ICU units. Such structures can be dismantled and reused into smaller structures for primary healthcare centres.

“To develop mass healthcare infrastructure in rural areas at affordable rates in the long run, we can introduce the foldable partitions at a large scale. Plus an acre worth of residue can fetch the farmers up to Rs 25,000 and simultaneously reduce air pollution by preventing stubble burning. Every 10×4 feet panel uses around 100 kilos of straw. It’s win-win for all,” adds Shriti.

Edited by Divya Sethu

No comments:

Post a Comment