The COVID-19 pandemic was a tough time for a lot of people, including businesses. The situation was bleak at Chikkamagaluru too, at BG Boutique Paper Mills Private Limited. BG Seetharaman, Founder and Managing Director of the company, faced a tough time in keeping the handmade paper company running.

Passionate about sustainability and preventing agricultural and plastic waste from entering the landfills, he used the time to brainstorm ideas to work on his dream project which was an-end-to-end solution that would prevent solid wastes from entering landfills. But how could that be done? By developing a machine that recycles waste at source.

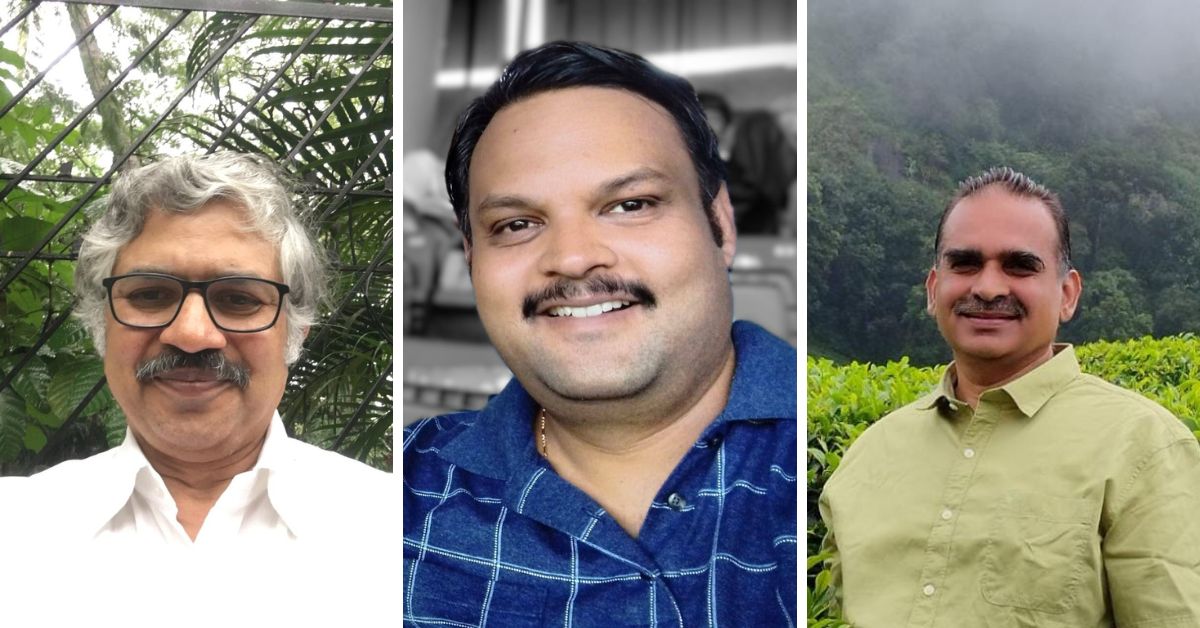

He discussed this idea with Vinay Kumar, a social entrepreneur, and Rajeeva Deekshit, a green chemical expert, over the next few months. They came to a conclusion that the two areas they wanted to target were waste paper and fibrous agricultural waste.

The problem, according to the founders is that, about 30,000 tonnes of paper is getting into the landfills due to being coated with plastic or aluminium and are contaminated with beverages that makes it unsuitable for recycling. On the other hand, almost 87 million tonnes of crop residue is burned annually in India, as per a Science Direct report.

To prevent this, the trio started Indic Initiatives in July 2022 and have developed a one of its kind waste paper recycler that tackles the difficult to recycle paper cups, label release paper, tissue papers and tetrapaks. Their machine recycles this waste into pulp boards, which can be further used to manufacture paper and moulded products.

Incubated at NSRCEL (IIM Bangalore) and IIMV FIELD (IIM Visakhapatnam), the startup is planning to patent the machine’s design and process.

Tackling the difficult to recycle plastics

A mechanical engineer from BITS Pilani, Seetharaman also pursued research at the Indian Institute of Science in Bengaluru. After working at Seshasayee Paper and Boards for a few years, he set up his own handmade paper unit in 1997, called BG Boutique Paper Mills.

Here, he claims that they make 100 percent recycled paper, paper bags and stationery from jute and cotton waste.

“We built a semi-automatic machine in 2014 as a ready-made paper machine was not available to our size, to process say 100-200 kg per day. We designed it to make paper from raw materials like jute waste, leather waste, banana waste and other unique raw materials,” Seetharaman shares with The Better India.

Since the cost of production was high, the first lockdown in 2020 caused a huge roadblock. Now, the engineer and scientist thought of developing a complete product which could recycle paper waste at source. He calls it an ‘end-to-end paper machine’.

The challenge lay in building technology which would recover clean plastic, by removing silicone coatings, hazardous substances and beverage stains.

Seetharaman had already worked with Rajeeva in 2017 to create a technology that removed glassine from label release papers.Their technology could recycle this silicone coated paper.

“Label release papers have a silicone coating which is hazardous and not recyclable. A big manufacturer had approached us to develop a technology to remove the coating and recover pulp. I knew that we could use the same technology for paper cups and tetra packs too,” adds Seetharaman.

Tetra packs too come coated with plastic or aluminium and are usually contaminated with beverages, tissue paper, and label release paper. Due to these complications, tetra packs and paper cups are not generally recycled, opines Seetharaman.

“We found that they are getting recycled efficiently because of their layers of plastic and aluminium. Separation of these layers is not done,” he adds.

Thanks to grants and awards after winning ELEVATE Karnataka 2023 and Nidhi Prayas 2023, they built a pilot plant in Chikkamagaluru, where they were able to efficiently separate plastic from the paper cups and silicone gum from silicone coated paper.

Today, they have a proof of concept at the minimum viable product capacity.

“Our unit can recover clean plastic and aluminium coatings for reuse, recover hazardous ink waste for reuse and upcycled fibrous agricultural wastes to create paper pulp that can be made into high-strength paper used for packaging,” says Vinay, Founder of Indic Initiatives.

A chartered accountant by education, Vinay is a social entrepreneur based in Bengaluru who started Indic to provide a platform for indigenous innovations that will benefit the country.

How the machine works

“Once the paper cups, tetra packs or tissues are received, they are manually put inside the recycling machine. The components go through a three-stage process. In the case of tetra packs, the machine uses a chemical suspension to separate it into aluminium, plastic and pulp. In the case of paper cups, it is separated into plastic and pulp. The pulp is then converted into pulp boards,” says Seetharaman.

These pulp boards are sold as raw materials for paper making or making moulded products. The aluminium and paper waste is sorted separately and given to recyclers.

Rajeeva states that they developed an eco-friendly solution which separates these aluminium, silicone and plastic from tetra packs and paper cups respectively.

Another unique aspect about the machine, says Seetharaman, is that there will be no effluents released by the machines.

“Both in the paper and agriculture machines, we have ensured that there is no effluent released. Even in the case of banana waste, we are looking at extracting the sap and using it as a liquid fertiliser. It will be a zero liquid discharge arrangement,” he adds.

Their machine is designed for villages, malls, airports and more. It comes with a capacity of recycling 50 kg of paper waste per day, which can be extended to 150 kg. A larger machine which can process up to one tonne is also available.

Currently, they are in talks with some village panchayats and malls in Karnataka and hope to launch soon.

“Transportation of paper waste for recycling to bigger plants is difficult and usually doesn’t happen. To prevent this, we must provide options to recycle at source. We want to ensure that all waste generated is converted to good quality pulp boards. We will facilitate a buyback model for the pulp and send it to a paper mill or moulded product unit to close the loop,” adds Seetharaman.

The goal is to ensure that every piece of waste, be it plastic or paper, is not sent to the landfills.

Edited by Padmashree Pande, Images Courtesy BG Seetharaman

No comments:

Post a Comment