In the midst of the COVID-19 pandemic, when his peers engaged themselves in making social media content, Mohammed Azhar Mohiuddin saw this as an opportunity to delve into entrepreneurship and tackle pressing issues such as plastic pollution.

From a young age, he dabbled in various ventures from website development, logo designing, to running a cloud kitchen to selling burgers from home. His entrepreneurial spirit was fueled by a desire to solve problems rather than solely chasing financial gains.

“In 2019, I wondered what I was really even chasing. Money? That would come even after I started focusing on solving real life problems,” he says.

While researching on top global environmental issues, Azhar found that there have been several awareness campaigns and protests worldwide on plastic pollution. “Unless we have an alternative, there is no way to curb plastic usage. While big brands can afford jute and cloth bags but medium and small businesses which comprise a bulk of the Indian market continue to use plastic bags,” he adds.

“One of the major reasons behind the extensive use of plastic bags are its properties. It is water resistant, thermal, durable, light-weight, and has good tensile strength. I wanted to find a solution that could mirror the properties of plastic while being eco-friendly and cheaper than paper, cloth, and jute alternatives,” he says.

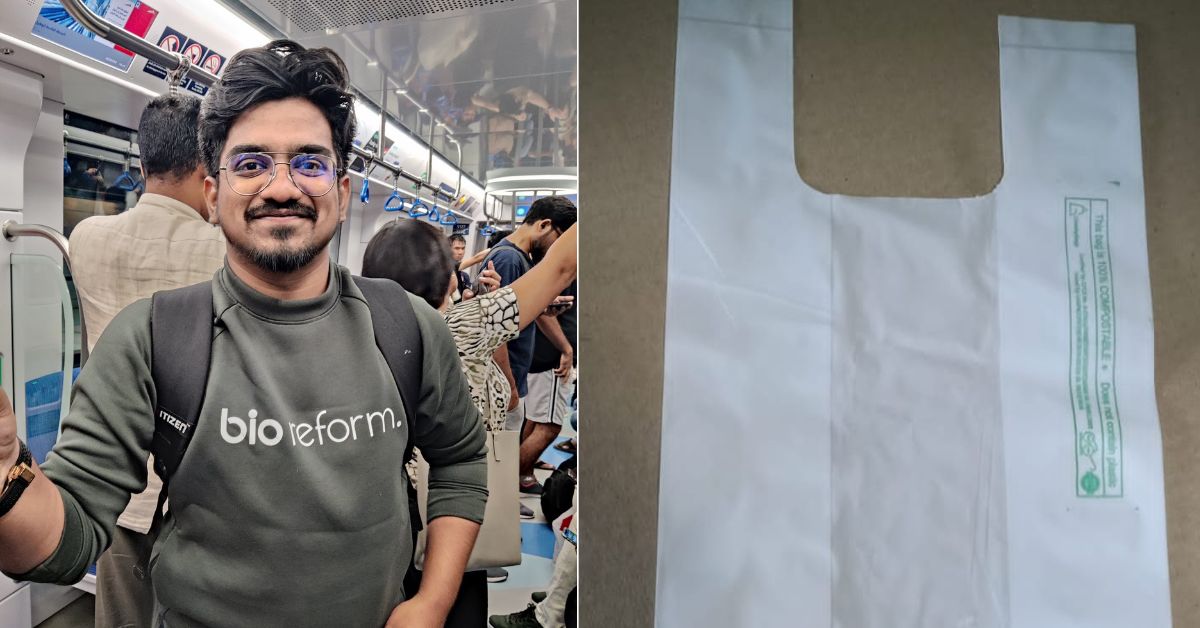

This quest led him to launch ‘Bio Reform’, a Hyderabad-based startup that manufactures compostable bags using corn waste, sugars, cellulose, and other natural components into sustainable biopolymers. In the past two years, it has replaced over six million plastic bags.

Challenges on the way

Azhar drew his inspiration from a biopolymer research paper dating back to the 1800s.

He started studying about a biodegradable polymer, PBAT (Polybutylene adipate-co-terephthalate), that is derived from plant-based sources such as corn and potatoes. This formed the basis of a new business endeavour for Azhar.

The next step was to find the right machinery to process the raw materials into end products. His determination was tested when he faced several setbacks such as encountering fraudulent schemes and operational difficulties in the early stages.

“My uncle and I went to Delhi to check the machinery after we came to know a seemingly promising opportunity but it turned out to be a scam. The contact person was not answering our calls and his promised location turned out to be a barren land. It was very traumatising for us. I had somehow convinced my parents and now I did not want to go back home empty-handed,” he says.

Determined not to let this setback deter them, Azhar and his uncle took a leap of faith and reached out to another contact in Gujarat, which came with its own series of challenges.

Landing during a curfew amidst the COVID-19 pandemic, Azhar had to spend most of the night stranded on the road as the hotel denied check-in due to a sudden RT-PCR report requirement. “But the perseverance paid off when we witnessed the machinery and its live demonstration the next morning,” he adds.

Around the same time, he received Rs 1 crore funding from the Adventure Park incubator programme. In early 2022, he inaugurated his factory in Hyderabad at the age of 22.

Replaced 6 million plastic bags

Setting up a manufacturing unit from scratch was itself challenging for Azhar. He had to manage the intricacies of a manufacturing business and the pressures of balancing academic commitments.

“On the inauguration day, my uncle, who was also the co-founder, quit the company citing some personal reasons. I tried to balance both my studies and the operations of the company – from collecting raw material, assisting workers to manufacture bags, delivering the products in the market. I used to sleep in a corner in the factory,” shares Azhar, who was then in the third year of his college.

This continued for a year but Azhar had to shut the factory down after he was unable to make profits to sustain the company. “I came back to zero. Meanwhile, I had 14-15 backlogs in my engineering. In a bid to balance both jobs, I failed at both. It was a stressful situation for me,” he adds.

Yet, through sheer grit and relentless effort, the civil engineer not only cleared all exams but also secured a funding from an investor, and eventually revived his enterprise in a couple of months.

Today, his company is manufacturing 4-5 lakh carry bags, biomedical waste bags, garbage bags, food pouches, and book wraps. Interestingly, Azhar says, these bags are compostable and can be decomposed within 180 days. In the last two years, his startup has replaced more than six million plastic bags by commercialising in the B2B chain.

Last year, he clocked an annual revenue of Rs 1.8 crore.

Mohd Sami Uddin, co-founder of Country Chicken Co, has been using Bio Reform bags for more than a year. Sharing his feedback, he tells The Better India, “We wanted to focus on sustainable packaging as much as possible. Prior to Bio Reform bags, we were using plastic bags. Later on, we also tried other sustainable bags but unfortunately, they were neither food grade quality nor superior.”

“At times, the customers would complain to us if some sharp bones would pop out from low-grade bags. However, Bio Reform bags meet all our requirements and can be easily sealed as well, similar to plastic. Besides, there was not much difference from the price point also. The plastic bags would cost us Rs 160 per kg whereas Bio Reform bags cost Rs 180 per kg,” he adds.

At the individual level, Azhar says that he has spearheaded a movement towards India’s vision to become single-use plastic-free.

“Issues related to plastic pollution are not limited to affecting aquatic life and animals anymore. Today, microplastic has reached our bloodstream. Bottled water contains microplastics. Addressing this is an important and urgent problem,” he says.

“I am glad I am able to contribute my part. It is sometimes taxing to not lead a regular college life but in the end, it is all worth it. I feel content when I go back to sleep. But much more needs to be done to make India plastic-free, and I will continue to strive for it,” he adds.

Edited by Padmashree Pande; All photos: Mohammed Azhar.

No comments:

Post a Comment