The 3D-printing technology is helping the healthcare industry advance by leaps and bounds. Whether it is building a cast using the scan of a broken arm, or printing new tissue and organs, 3D printing provides customised solutions for patients.

In a new wave of technology and discovery, a scientist from the Indian Institute of Technology (IIT) Madras has made use of this technology in the most astonishing way.

Ikram Khan, along with researchers at Massachusetts Institute of Technology (MIT), has developed a low-cost 3D-printed system that enables the growth of brain tissue or brain organoids.

Brain organoids are biological systems grown in Petri dishes or incubated conditions. These live models are used to study the development of brain tissues and neurological disorders. Moreover, this helps to understand how to treat and provide the right medication for such disorders.

“With 3D printers and biocompatible resin used for dental surgeries we were able to build a palm-sized system that can be used to grow tiny brains. The system costs only $5 [Rs 375] per unit to fabricate which is cheaper than a bucket of KFC chicken,” says Ikram, adding that conventional systems currently being used are expensive and require physical interference. This could lead to contamination and other complications in the research process.

In an interview with The Better India, Ikram Khan shares why and how he went about innovating this low-cost technology.

Project to prototype

In 2019, when Ikram was pursuing his final year of Master’s in Electrical Engineering he was working on a project related to Neural Brain Imaging technology. It was then that he learnt there is no simple method to develop organoids without spending a lot of money.

“The methods currently in use require incubation systems which are placed in 10×10 feet rooms. While growing organoids, it is important to provide nutrition such as amino acids, salts and glucose to the tissue. And, regularly diagnose and analyse developments. But, because they are placed in a closed environment researchers need to physically intervene to do these activities. This can lead to contamination causing the developing cells to die,” says the 28-year-old.

However, developing organoids is vital in medical research because it helps to understand how any disorder develops so that it can be treated or prevented at early stages. So, Ikram started to work on a system that would be devoid of human intervention. He focussed mainly on developing a device to grow cerebral organoids.

“I submitted a research proposal to MIT because they have the best biomedical engineering laboratory and facilities. In July 2019, my proposal was accepted by them and I was allowed to continue my research along with three scholars and a professor there,” says Ikram, adding that he spent two months working in the USA.

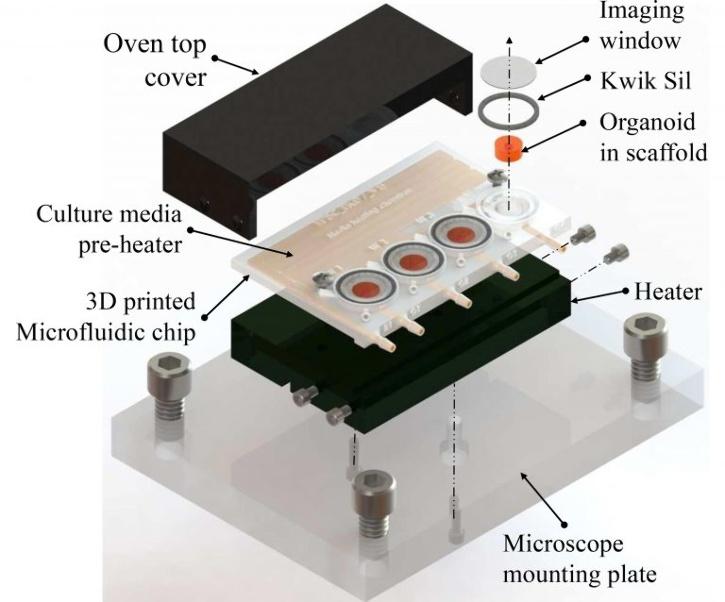

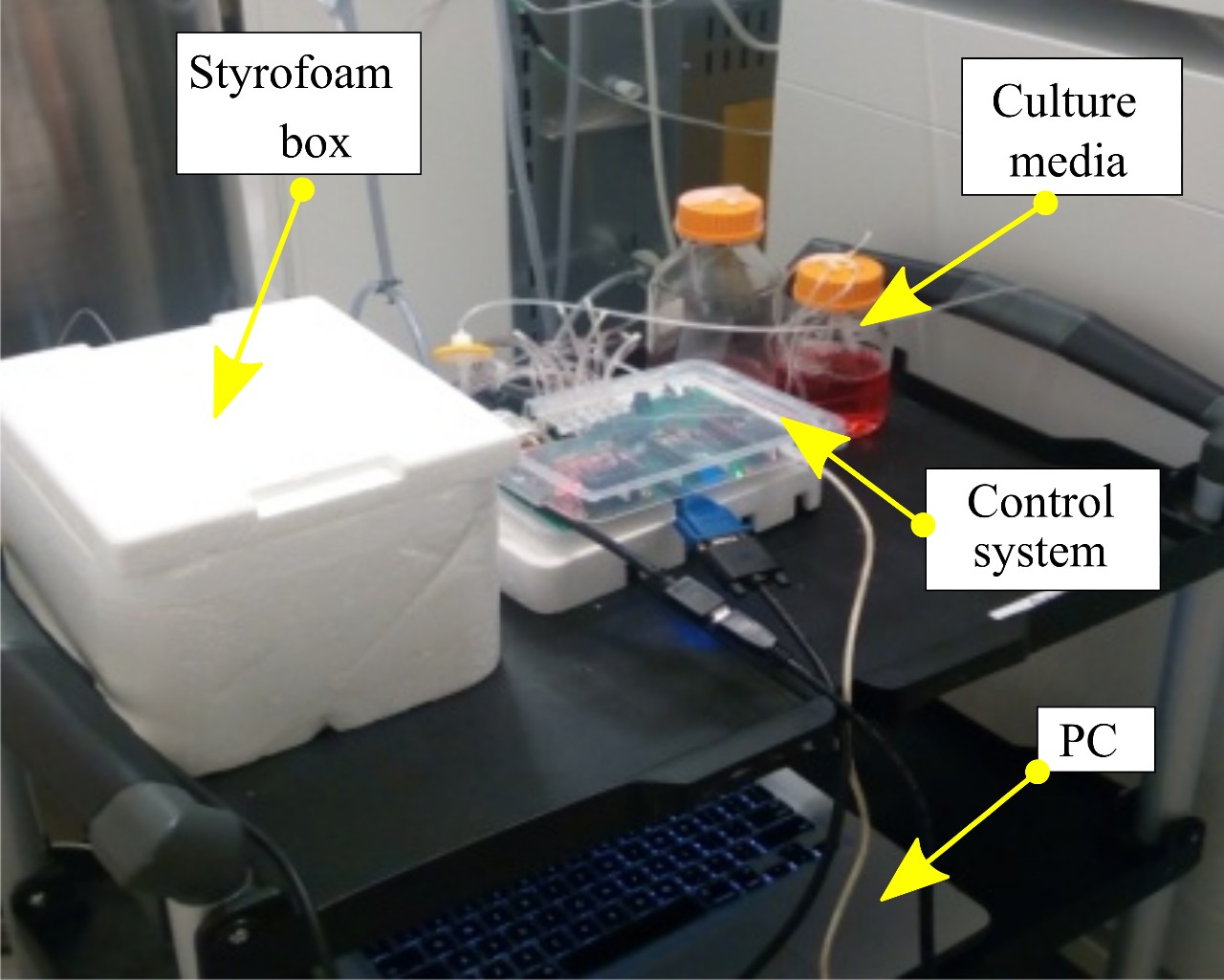

The team developed a palm-sized device named ‘Microfluidic Bioreactor’ using a 3D printer and biocompatible resin used for dental surgeries. It is powered by electricity. However, with built-in real-time imaging and automatic pumping of nutrients, this system requires no physical intervention.

“The real-time imaging cameras monitor necessary vitals to understand the growth of the cells and tissues. The growing platform has tubes that mimic human veins to supply the necessary fluids,” says Ikram.

A better system

By September 2019, the final prototype was designed and the researchers began conducting lab-level tests to determine its effectiveness. For comparison purposes, they grew brain tissue in incubated conditions and they grew the same using the microfluidic bioreactor.

“Within one week, the cells in incubation began to die owing to contamination whereas the other specimens continued growing. It also provided real-time high-quality images which helped to study cell development over some time,” says Ikram.

Once he returned to India, Ikram planned to manufacture this system on an industrial scale and help accelerate research across many fields. In September 2020, he launched ISMO Bio-Photonics Pvt Ltd, an IIT-M incubated company.

“Through the startup, I am looking to develop these systems on a larger scale and collaborate with educational institutions to conduct research using these devices,” says Ikram.

No comments:

Post a Comment